21 Jun Equivalent Stress

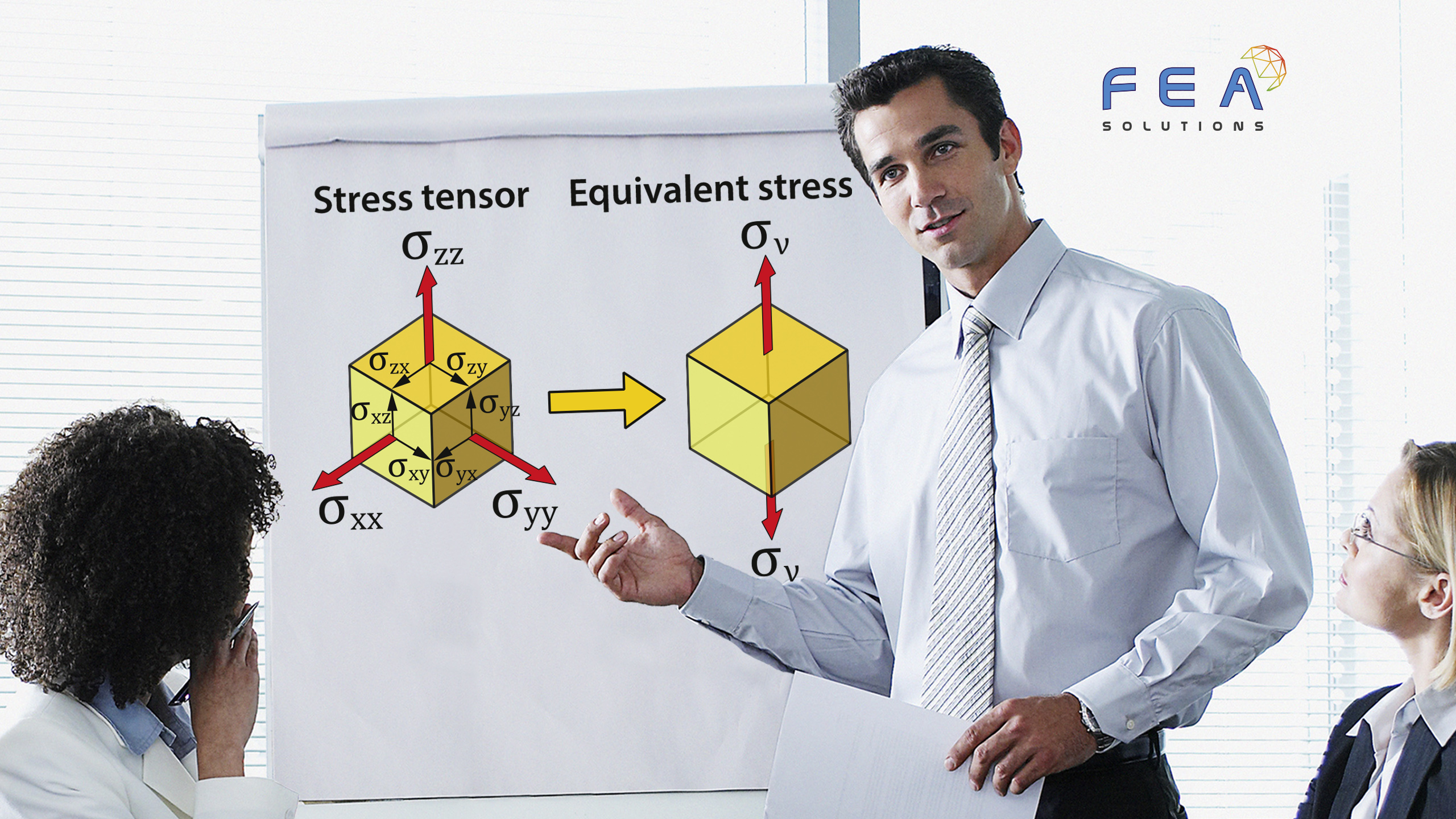

The stress results of a FE analysis are three-dimensional tensors, see: (https://fea-solutions.co.uk/stress-tensor/)

Material properties including Yield Strength and Ultimate Strength are however usually derived from uniaxial tests, e.g. tensile tests, see: (https://fea-solutions.co.uk/tensile-tests/)

Depending on the material used and its failure mode, there are different conversions done:

- For ductile materials (e.g. many commonly used metals), the Von Mises stress is calculated. This is the most common equivalent stress in mechanical engineering and hence frequently referred to as the Equivalent Stress (although there are others).

- Some pressure vessel codes require Tresca Stress to be used.

- Ceramics (including glass) have a high compressive strength but a low tensile strength. That is why the Maximum Principal Stress is used to asses these materials.

- Fibre Reinforced Plastics (FRP) are strong in tension but less strong in compression. That is why they are compared to the Minimum Principal Stress.

- Particular equivalent stresses might be required for certain engineering codes.

FEA programs convert the stress tensor automatically to the desired equivalent stress. When reviewing a FEA stress report, it is however important to ensure that the appropriate equivalent stress has been applied.

Please call us today on +44 (0) 1202 798991 to let us solve your engineering problems.