22 May Plasticity Material Models

For the majority of all stress analyses, a linear-elastic material model (https://fea-solutions.co.uk/elasticity-and-plasticity/) is used because plasticity is not permitted for most applications. However, if plasticity does need to be included, several different types of material models can be used.

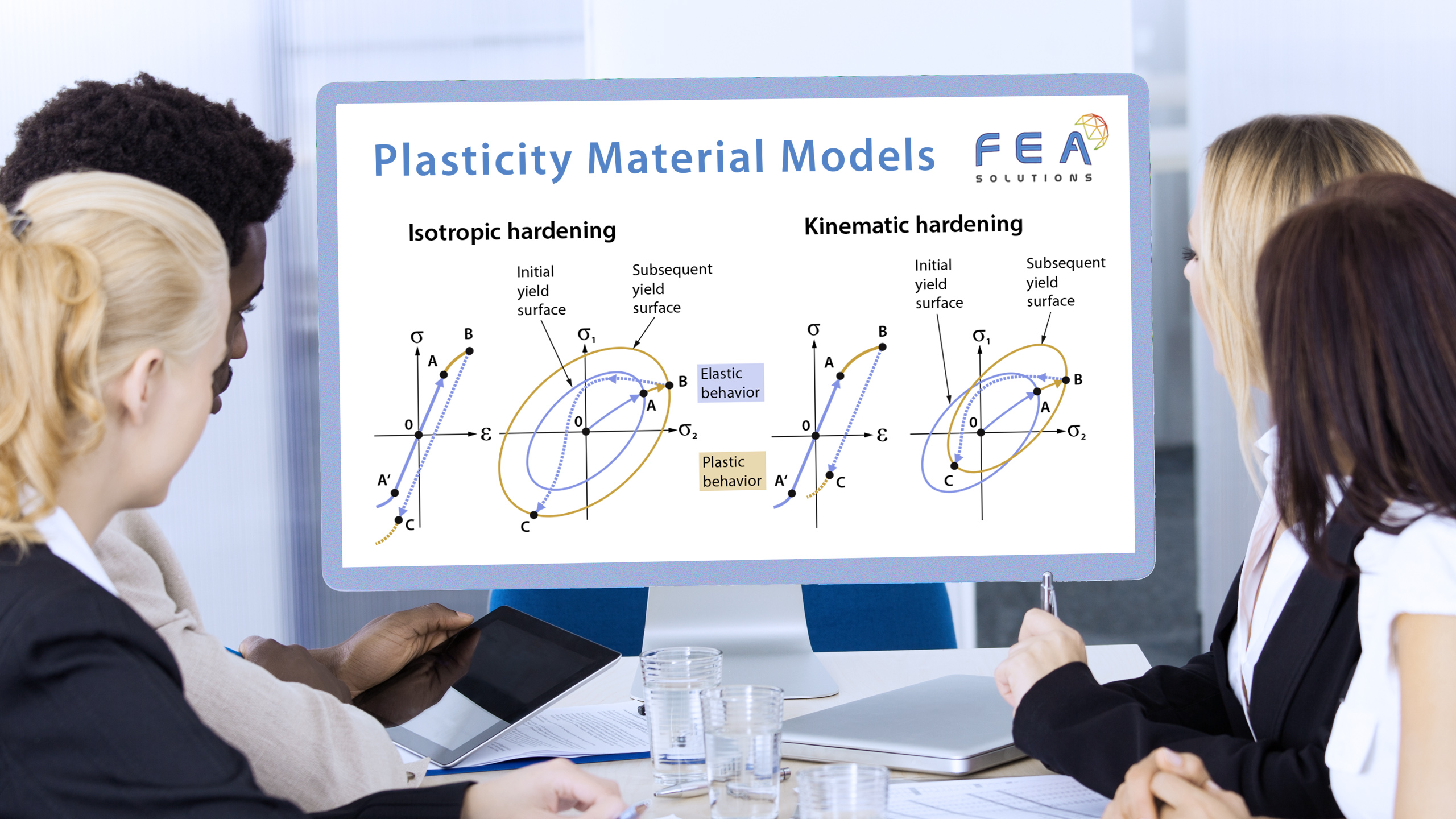

The two main groups of plasticity models are Isotropic Hardening or Kinematic Hardening. These theories are used for isotropic materials, in particular metals, that undergo cyclic loading. If a part is loaded just once, then both material models provide identical results.

Strain Hardening means that if a material is first loaded beyond yield and then unloaded, the material will strengthen, and when it is loaded a second time, it will stay entirely in the elastic region.

Isotropic Hardening means that after a material has been once tensioned beyond yield, that material will have a higher elastic limit for both tension and compression.

Kinematic Hardening means that if a material has been once tensioned beyond yield, that material will have a higher elastic limit just for tension but not for compression. Consequently, if the material were to be compressed after the initial tension, the elastic limit under compression is lower than that under tension.

Due to the big difference explained above, the choice of the material models only matters if the load applied changes direction. If the load direction does not change, both models will provide identical results.

Although these are the main two types of plasticity models, there are many others used for more specific applications.

Please call us today on +44 (0)1202 798991 for any engineering analysis requirements you might have.