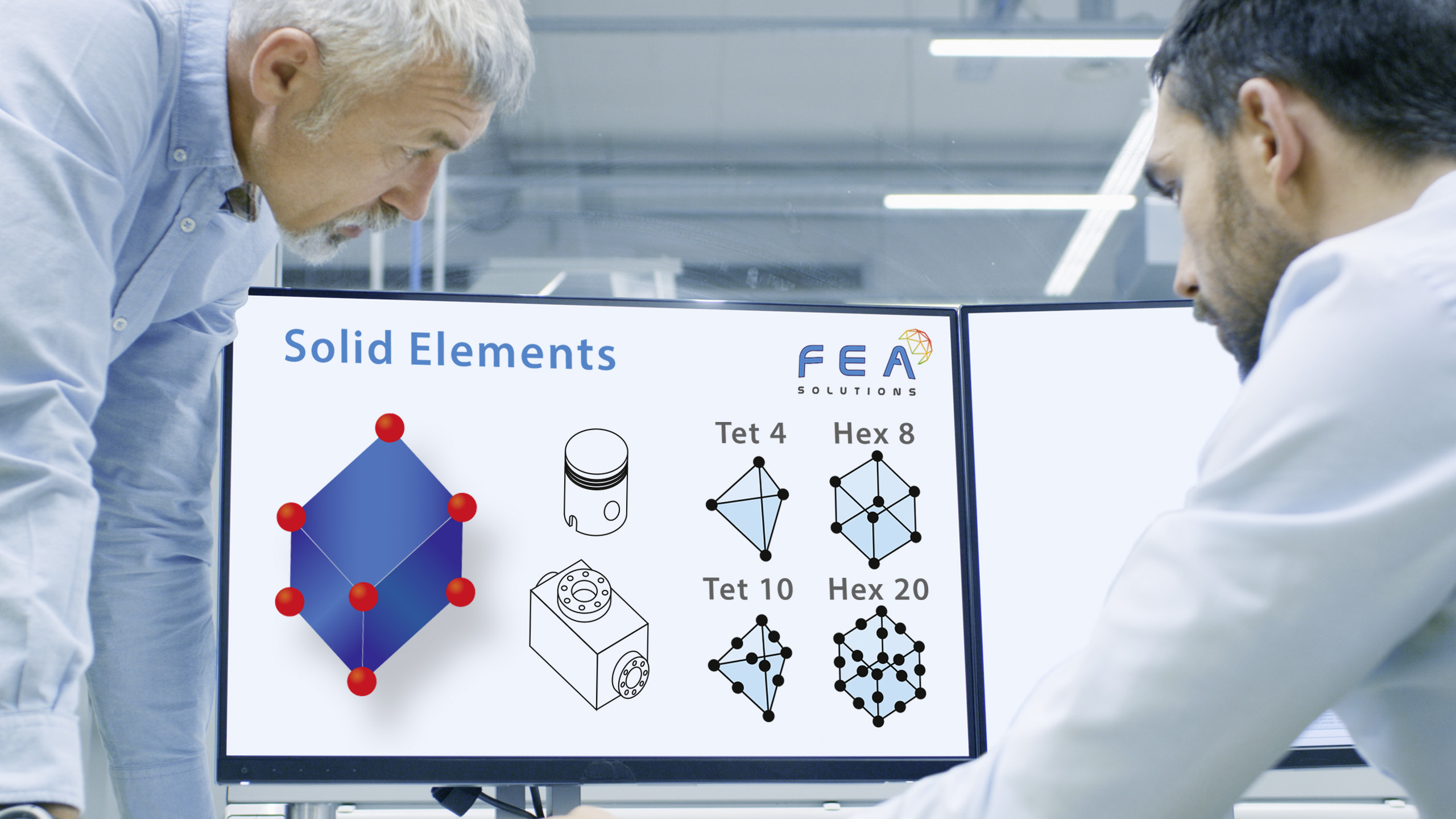

06 Dec Solid Elements

Solid Elements can have anywhere between 4 corner nodes (for Tetrahedral Elements) and 8 corner nodes (for Hexahedral Elements).

Solid Elements are used where all three dimensions of the part are comparable. They are used on most complex parts. Anything that is machined, cast or forged will often be represented by Solid Elements.

On Solid Elements, the nodes support only 3 Degrees of Freedom (DOF), the Translational DOFs, and so multiple elements across a part thickness must be used to accurately account for out of plane bending loads.

A variation of 3D Solid Elements are 2D Solid Elements (not to be confused with surface elements). They support only 2 DOF, and, depending on the type, simulate only in-plane or axisymmetric stress and strain.

Solid Elements are the most frequent element type used by automatic mesh generators in FEA software, as they can be applied to any CAD solid models. Depending on the geometry, Line Elements or Surface Elements might however produce more realistic simulation results.

Please call us today on 01202 798991 for free, competent advice on your simulation needs.